OUR NEW MEMS SWITCH

OUR NEW MEMS SWITCH

Smaller. Faster. Longer life. Higher current density.

Smaller. Faster. Longer life. Higher current density.

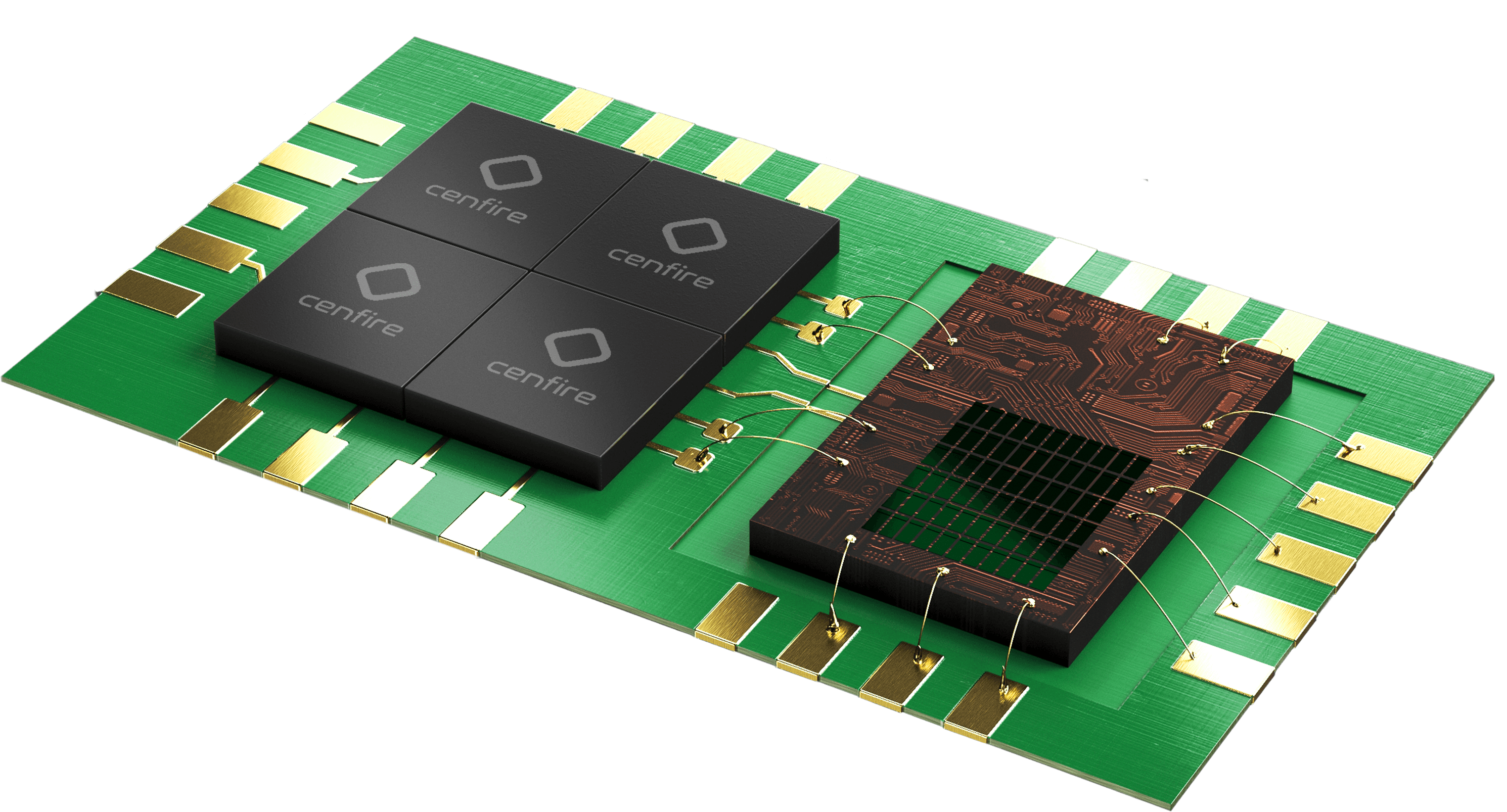

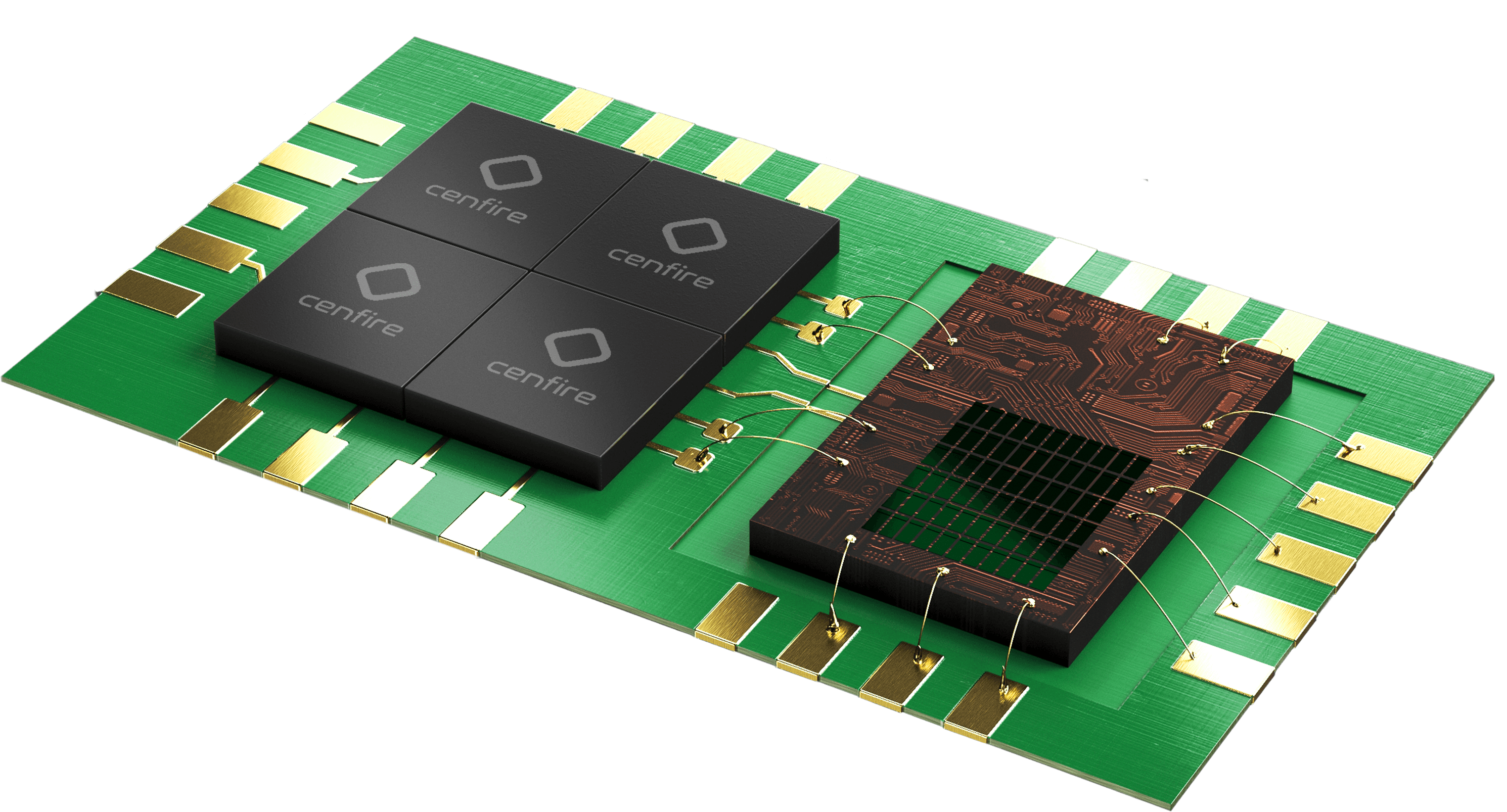

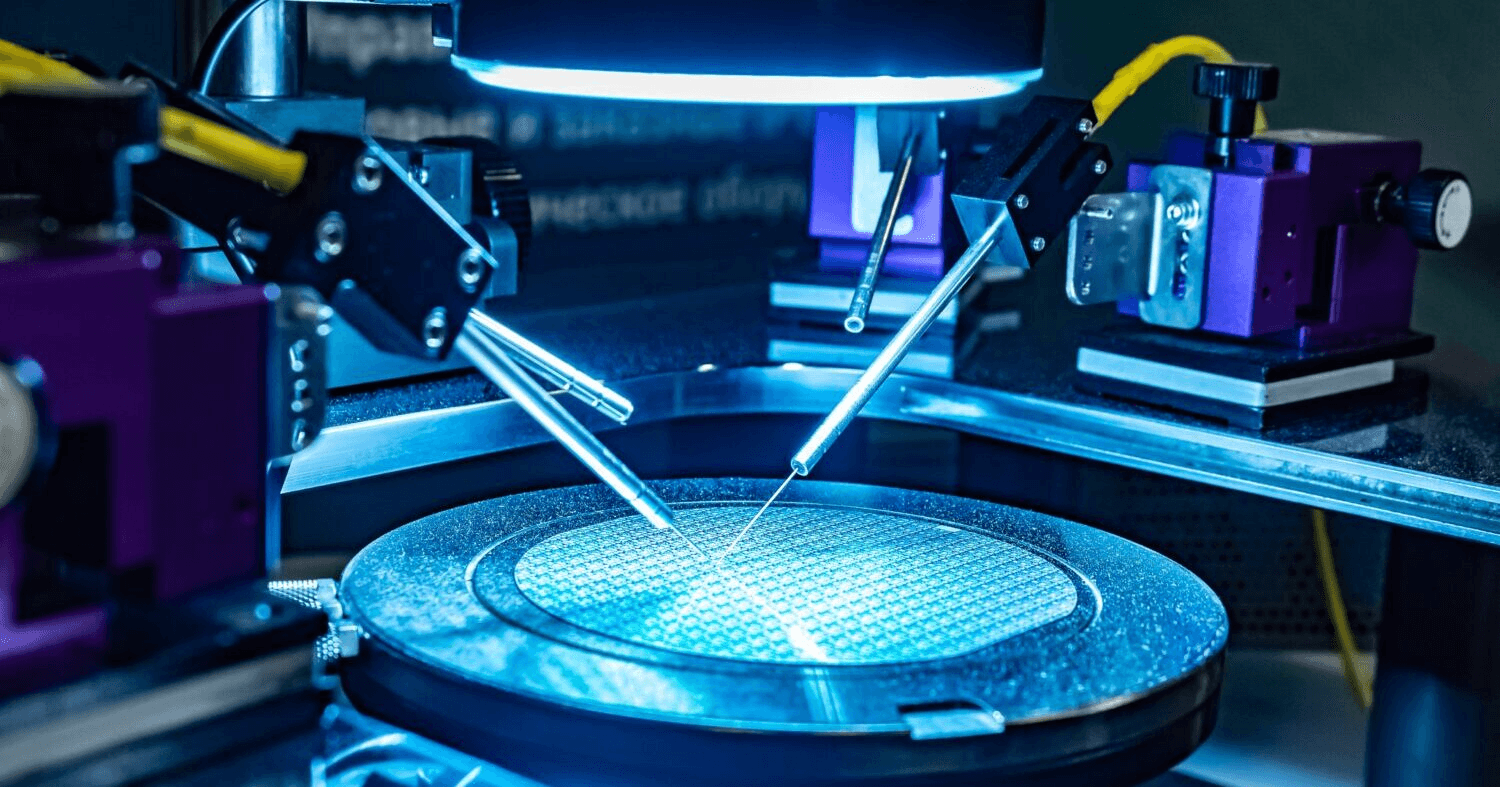

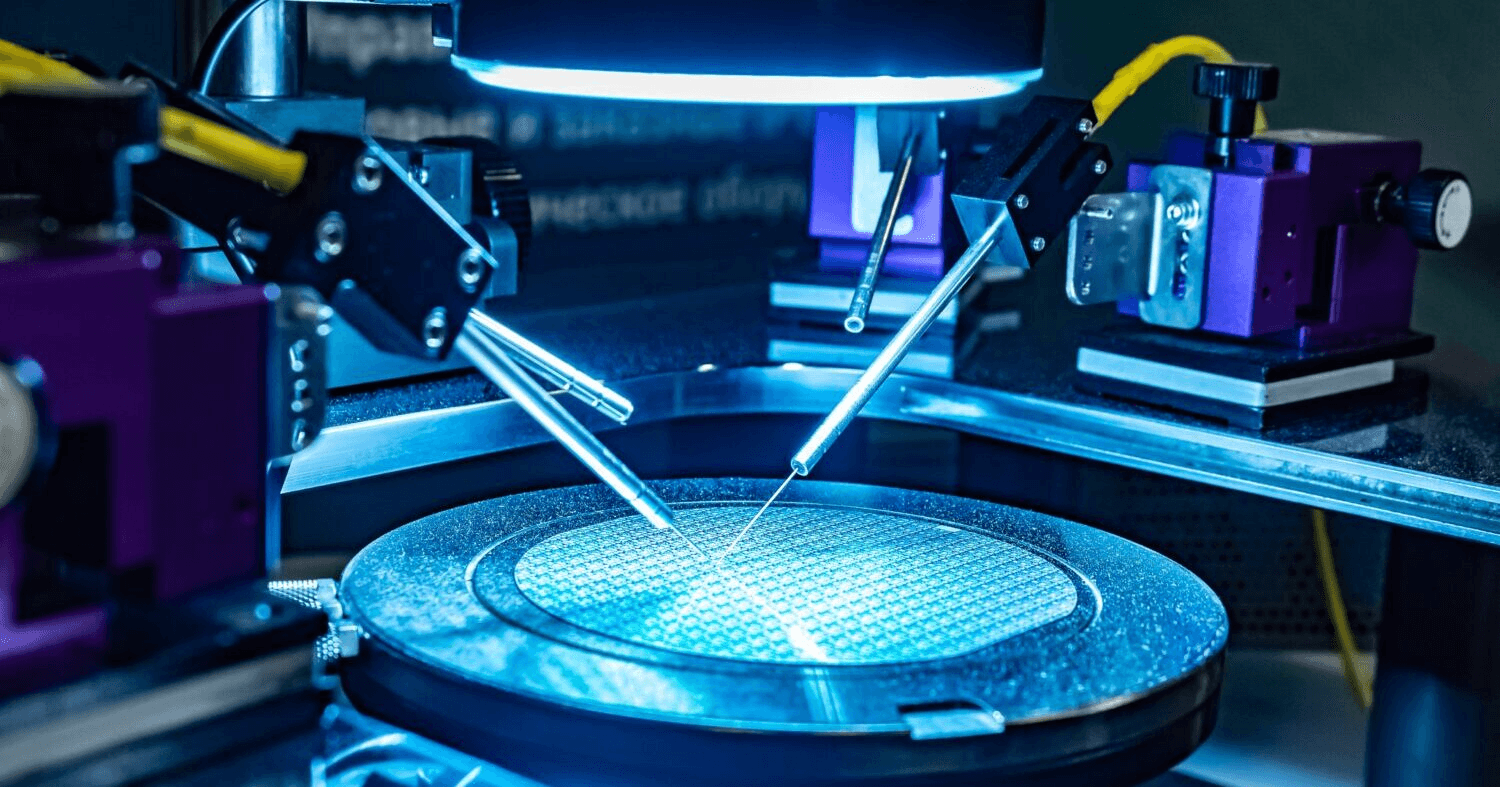

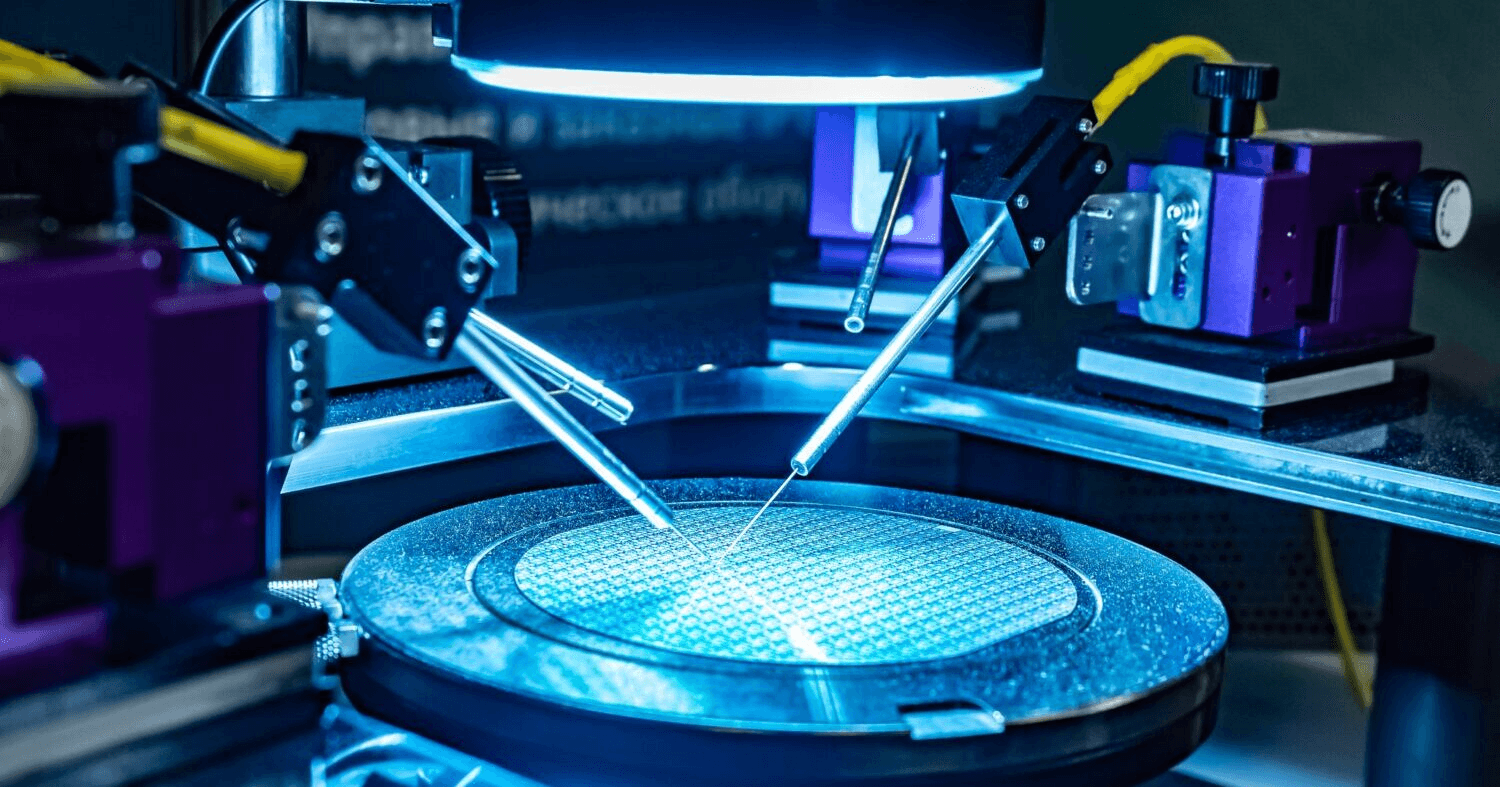

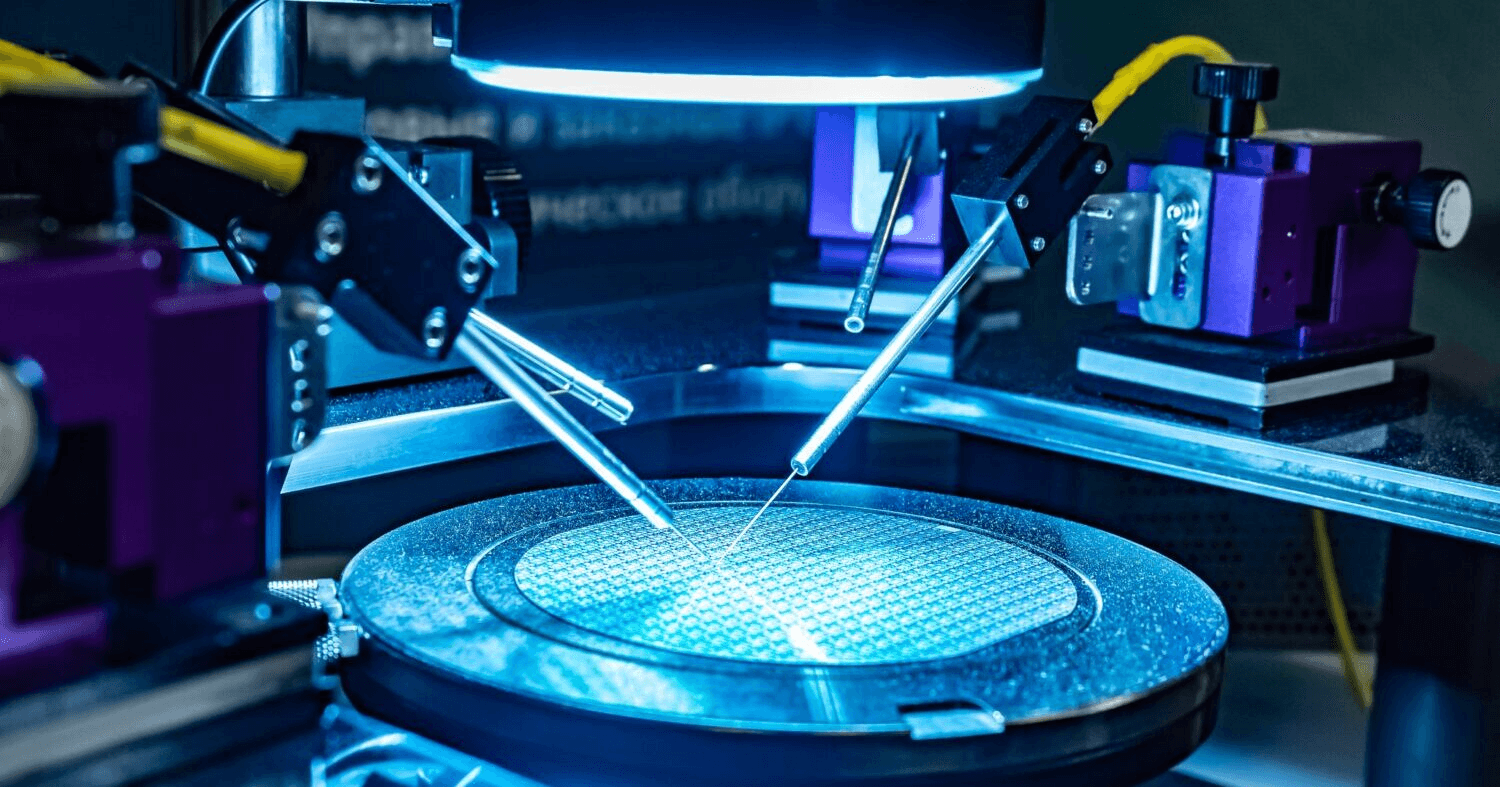

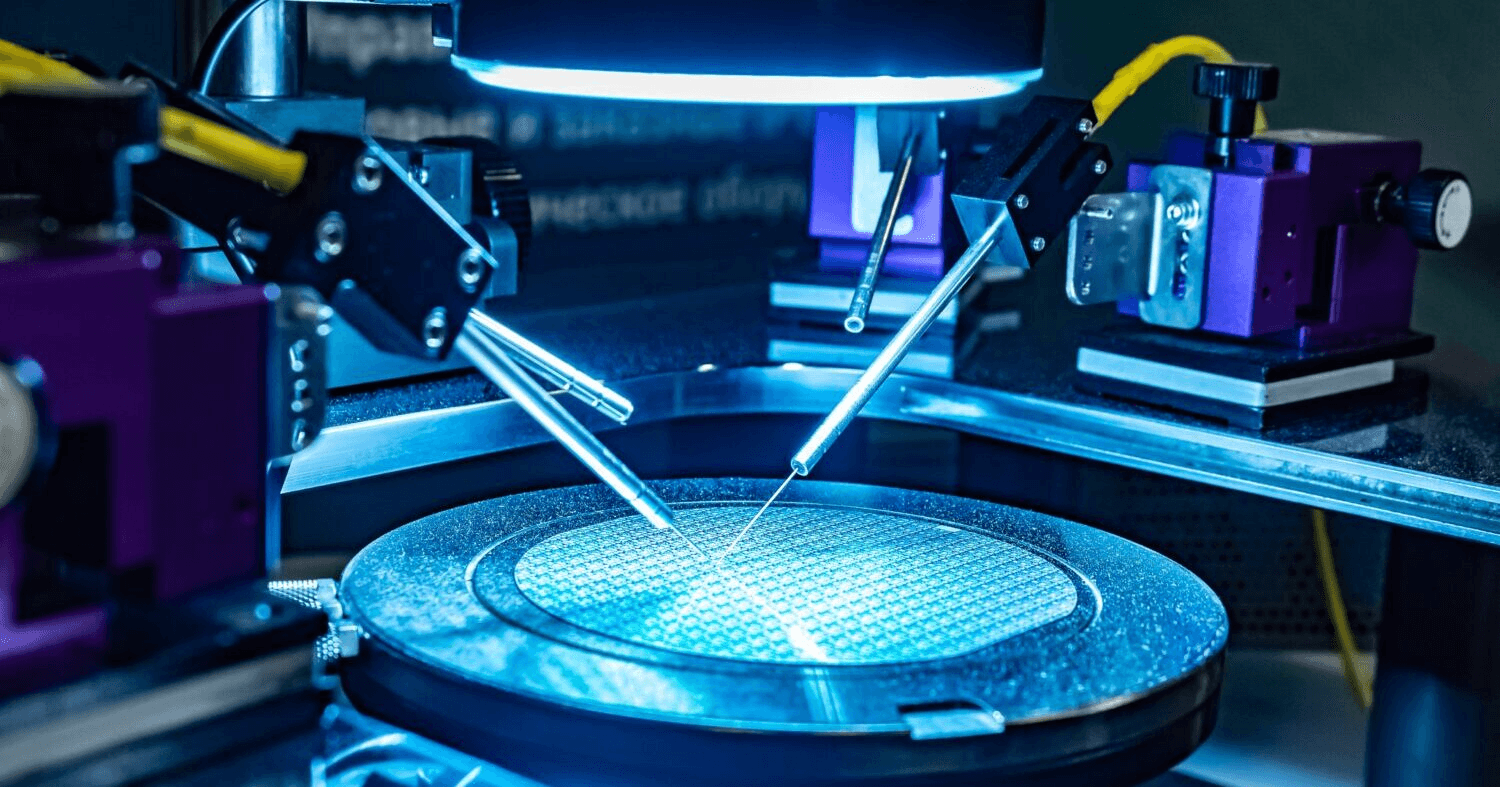

We’ve perfected a MEMS ohmic contact relay, which is highly configurable for RF and high-power DC applications (up to 40A and above). We’ve succeeded where many companies have failed by creating an extremely small switching technology platform that is manufacturable, scalable, and capable of the highest current density of any switch in the world — over one amp through our switches unit cell (a component only 1mm x 1mm in size).

We’ve perfected a MEMS ohmic contact relay, which is highly configurable for RF and high-power DC applications (up to 40A and above). We’ve succeeded where many companies have failed by creating an extremely small switching technology platform that is manufacturable, scalable, and capable of the highest current density of any switch in the world — over one amp through our switches unit cell (a component only 1mm x 1mm in size).

We’ve perfected a MEMS ohmic contact relay, which is highly configurable for RF and high-power DC applications (up to 40A and above). We’ve succeeded where many companies have failed by creating an extremely small switching technology platform that is manufacturable, scalable, and capable of the highest current density of any switch in the world — over one amp through our switches unit cell (a component only 1mm x 1mm in size).

We’ve perfected a MEMS ohmic contact relay, which is highly configurable for RF and high-power DC applications (up to 40A and above). We’ve succeeded where many companies have failed by creating an extremely small switching technology platform that is manufacturable, scalable, and capable of the highest current density of any switch in the world — over one amp through our switches unit cell (a component only 1mm x 1mm in size).

We’ve perfected a MEMS ohmic contact relay, which is highly configurable for RF and high-power DC applications (up to 40A and above). We’ve succeeded where many companies have failed by creating an extremely small switching technology platform that is manufacturable, scalable, and capable of the highest current density of any switch in the world — over one amp through our switches unit cell (a component only 1mm x 1mm in size).

>10x Smaller

>10x Smaller

>10x Smaller

Only 0.1cm³

Only 0.1cm³

Size

Smaller relays translate into more switching capacity in a smaller space with less weight. Regardless of market or industry, a smaller size generally leads to greater product innovation, lower overall costs, and competitive advantage. MEMS can be installed in locations impossible for full-size components. Without MEMS, smartphones and electronic wearables would not enjoy essential features, and certain modern products would simply not exist.

Traditional relays have been large and heavy. Cenfire's MEMS platform is hundreds of times smaller and still easily customizable.

Smaller relays translate into more switching capacity in a smaller space with less weight. Regardless of market or industry, a smaller size generally leads to greater product innovation, lower overall costs, and competitive advantage. MEMS can be installed in locations impossible for full-size components. Without MEMS, smartphones and electronic wearables would not enjoy essential features, and certain modern products would simply not exist.

Traditional relays have been large and heavy. Cenfire's MEMS platform is hundreds of times smaller and still easily customizable.

Smaller relays translate into more switching capacity in a smaller space with less weight. Regardless of market or industry, a smaller size generally leads to greater product innovation, lower overall costs, and competitive advantage. MEMS can be installed in locations impossible for full-size components. Without MEMS, smartphones and electronic wearables would not enjoy essential features, and certain modern products would simply not exist.

Traditional relays have been large and heavy. Cenfire's MEMS platform is hundreds of times smaller and still easily customizable.

Smaller relays translate into more switching capacity in a smaller space with less weight. Regardless of market or industry, a smaller size generally leads to greater product innovation, lower overall costs, and competitive advantage. MEMS can be installed in locations impossible for full-size components. Without MEMS, smartphones and electronic wearables would not enjoy essential features, and certain modern products would simply not exist.

Traditional relays have been large and heavy. Cenfire's MEMS platform is hundreds of times smaller and still easily customizable.

Smaller relays translate into more switching capacity in a smaller space with less weight. Regardless of market or industry, a smaller size generally leads to greater product innovation, lower overall costs, and competitive advantage. MEMS can be installed in locations impossible for full-size components. Without MEMS, smartphones and electronic wearables would not enjoy essential features, and certain modern products would simply not exist.

Traditional relays have been large and heavy. Cenfire's MEMS platform is hundreds of times smaller and still easily customizable.

>10x Faster

>10x Faster

>10x Faster

10us

10us

Switching Speed

Cenfire's MEMS platform will respond in under ten microseconds – hundreds of times faster than conventional components – and will do so reliably time after time after time.

Cenfire's MEMS platform will respond in under ten microseconds – hundreds of times faster than conventional components – and will do so reliably time after time after time.

Cenfire's MEMS platform will respond in under ten microseconds – hundreds of times faster than conventional components – and will do so reliably time after time after time.

Cenfire's MEMS platform will respond in under ten microseconds – hundreds of times faster than conventional components – and will do so reliably time after time after time.

Cenfire's MEMS platform will respond in under ten microseconds – hundreds of times faster than conventional components – and will do so reliably time after time after time.

60x Longer Life

60x Longer Life

60x Longer Life

1B Switching Cycles

1B Switching Cycles

Lifetime

In a conventional MEMS switch, the cantilever beam flexes at one point, just past its anchor. Repeated cycling of the switch causes the metal to fatigue, leading to the potential failure of the switch, typically in the closed position.

With Cenfire, the fatigue problem is solved through the core design.

Though specified to withstand one billion cycles, Cenfire's platform has been successfully tested to as many as 6.5 billion cycles.

In a conventional MEMS switch, the cantilever beam flexes at one point, just past its anchor. Repeated cycling of the switch causes the metal to fatigue, leading to the potential failure of the switch, typically in the closed position.

With Cenfire, the fatigue problem is solved through the core design.

Though specified to withstand one billion cycles, Cenfire's platform has been successfully tested to as many as 6.5 billion cycles.

In a conventional MEMS switch, the cantilever beam flexes at one point, just past its anchor. Repeated cycling of the switch causes the metal to fatigue, leading to the potential failure of the switch, typically in the closed position.

With Cenfire, the fatigue problem is solved through the core design.

Though specified to withstand one billion cycles, Cenfire's platform has been successfully tested to as many as 6.5 billion cycles.

In a conventional MEMS switch, the cantilever beam flexes at one point, just past its anchor. Repeated cycling of the switch causes the metal to fatigue, leading to the potential failure of the switch, typically in the closed position.

With Cenfire, the fatigue problem is solved through the core design.

Though specified to withstand one billion cycles, Cenfire's platform has been successfully tested to as many as 6.5 billion cycles.

In a conventional MEMS switch, the cantilever beam flexes at one point, just past its anchor. Repeated cycling of the switch causes the metal to fatigue, leading to the potential failure of the switch, typically in the closed position.

With Cenfire, the fatigue problem is solved through the core design.

Though specified to withstand one billion cycles, Cenfire's platform has been successfully tested to as many as 6.5 billion cycles.

>10x More Current

>10x More Current

>10x More Current

1A/mm²

1A/mm²

Current Density

Cenfire's platform can carry over one amp of current across a 1 mm x 1 mm component – ten times the capacity of competing technologies and coming close to the current density of a plain copper wire.

This is possible due to Cenfire's use of silicon in both the substrate and the armature’s supporting structure.

Cenfire's platform can carry over one amp of current across a 1 mm x 1 mm component – ten times the capacity of competing technologies and coming close to the current density of a plain copper wire.

This is possible due to Cenfire's use of silicon in both the substrate and the armature’s supporting structure.

Cenfire's platform can carry over one amp of current across a 1 mm x 1 mm component – ten times the capacity of competing technologies and coming close to the current density of a plain copper wire.

This is possible due to Cenfire's use of silicon in both the substrate and the armature’s supporting structure.

Cenfire's platform can carry over one amp of current across a 1 mm x 1 mm component – ten times the capacity of competing technologies and coming close to the current density of a plain copper wire.

This is possible due to Cenfire's use of silicon in both the substrate and the armature’s supporting structure.

Cenfire's platform can carry over one amp of current across a 1 mm x 1 mm component – ten times the capacity of competing technologies and coming close to the current density of a plain copper wire.

This is possible due to Cenfire's use of silicon in both the substrate and the armature’s supporting structure.

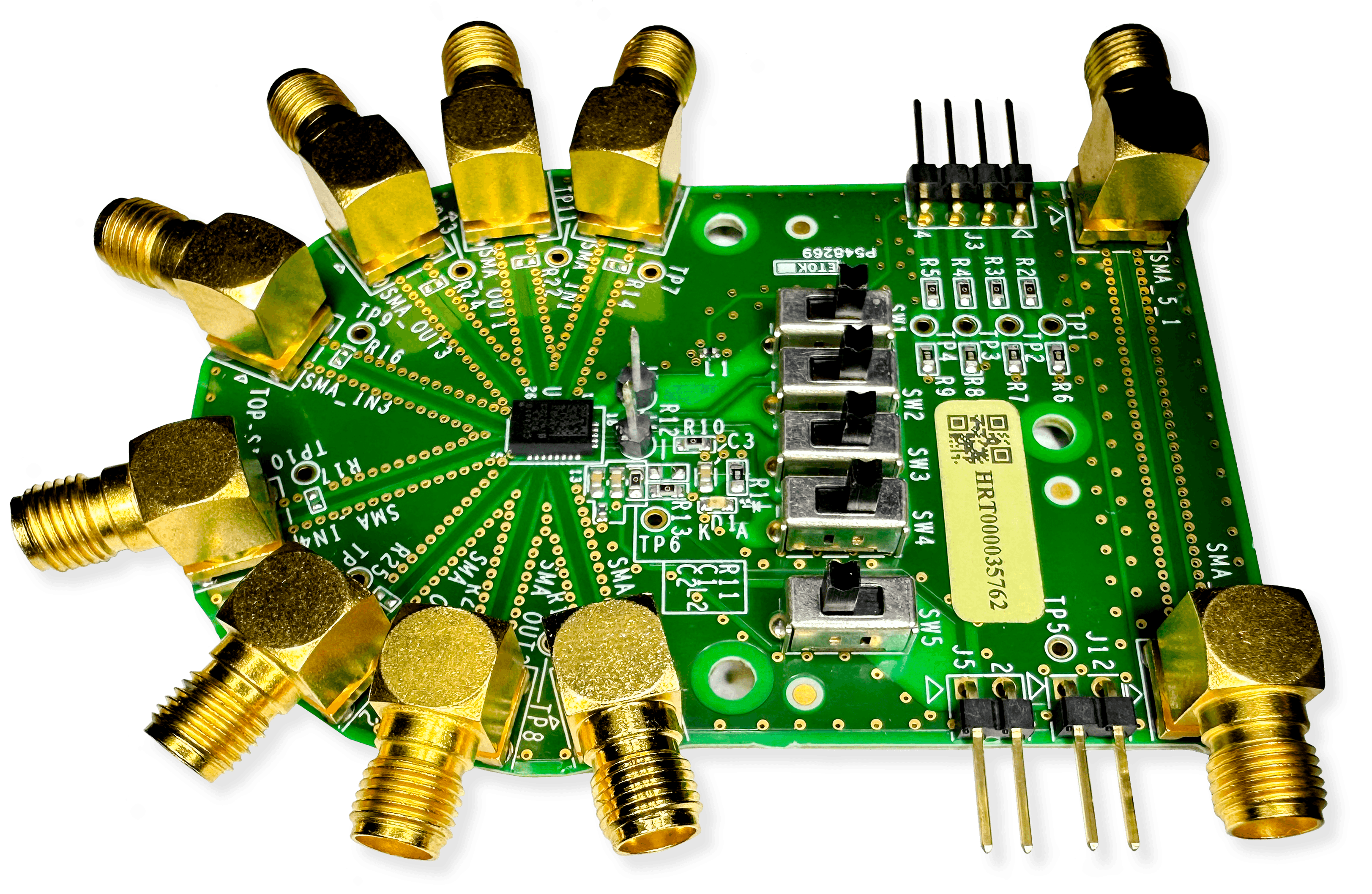

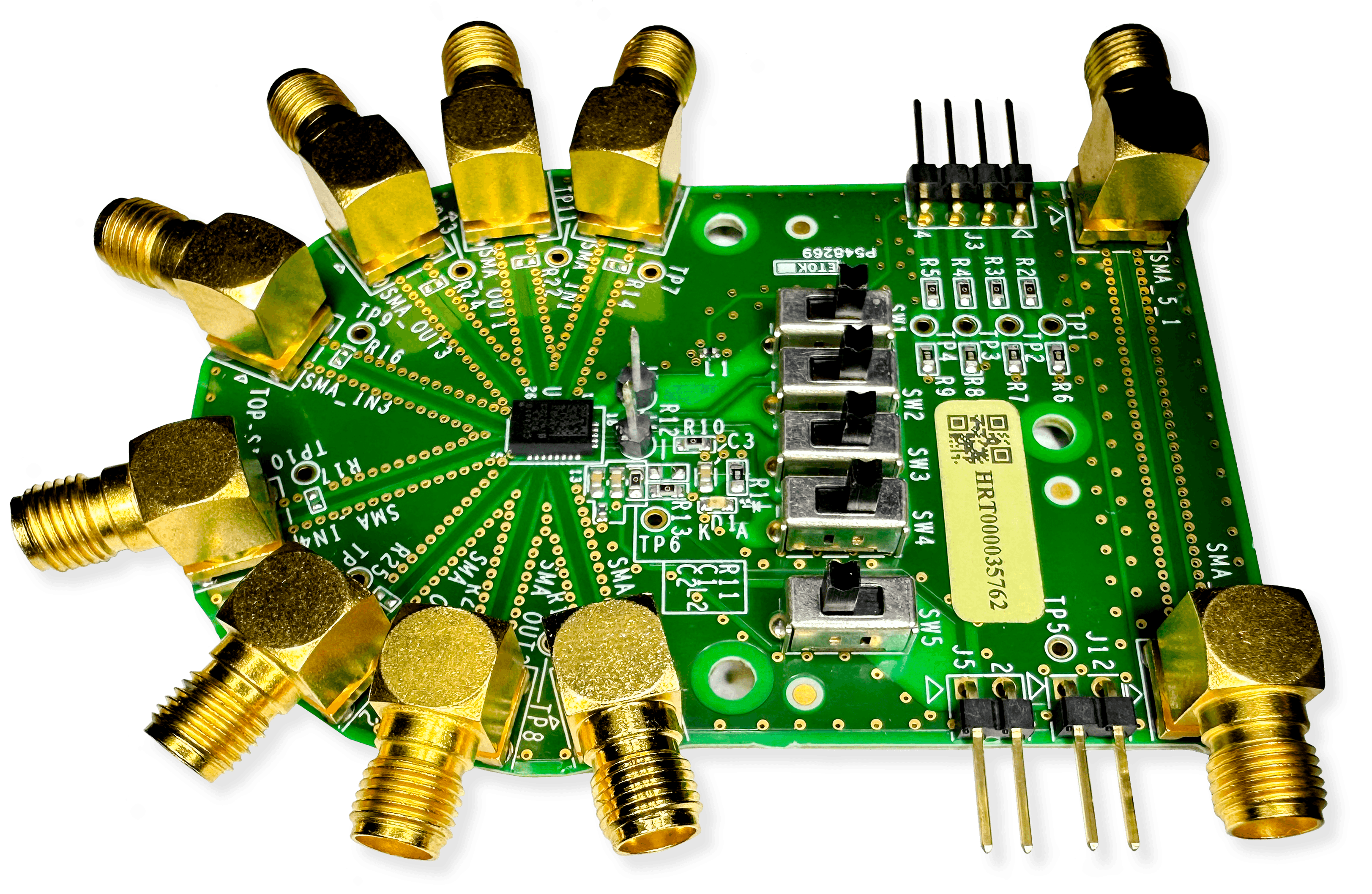

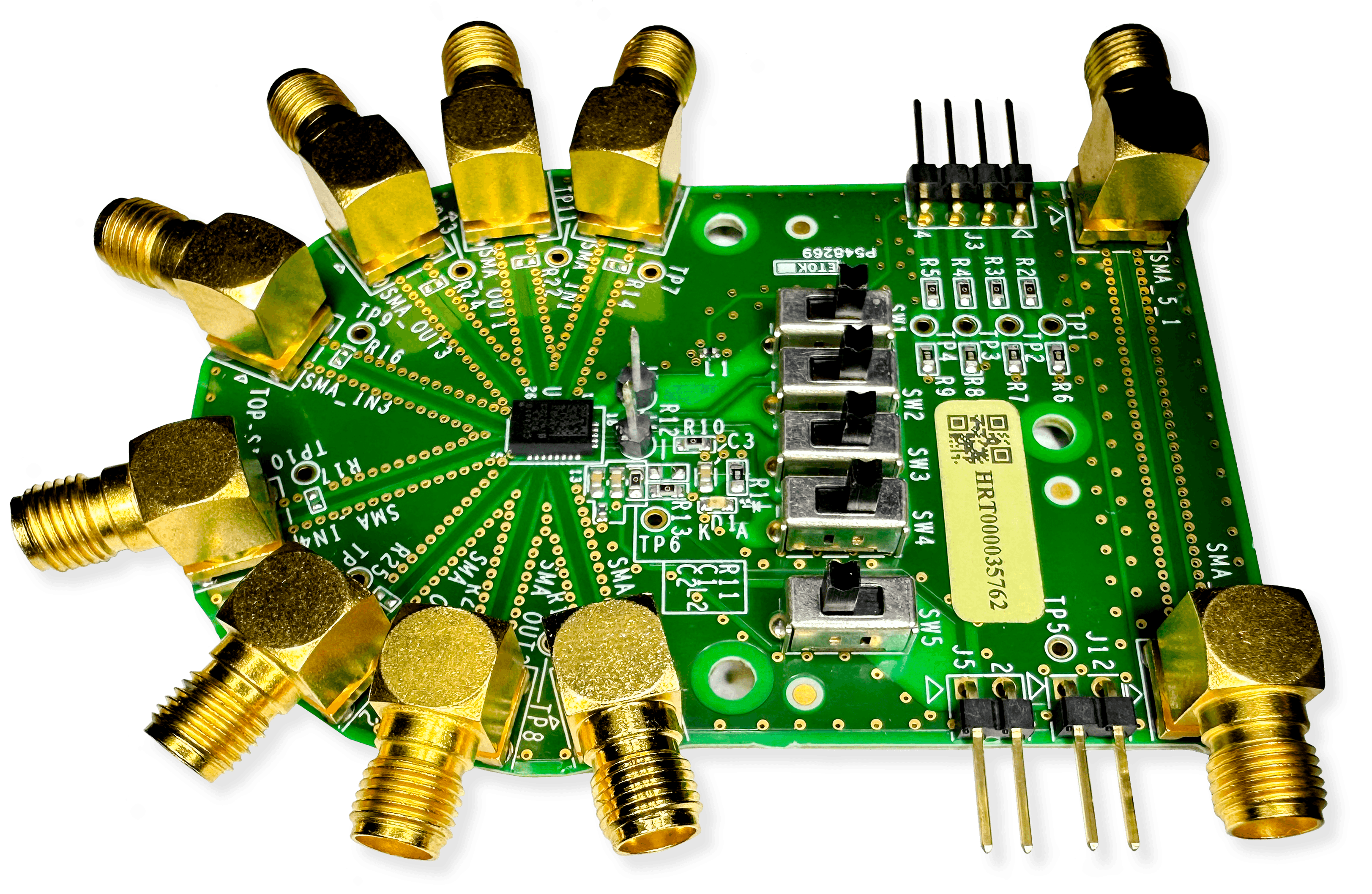

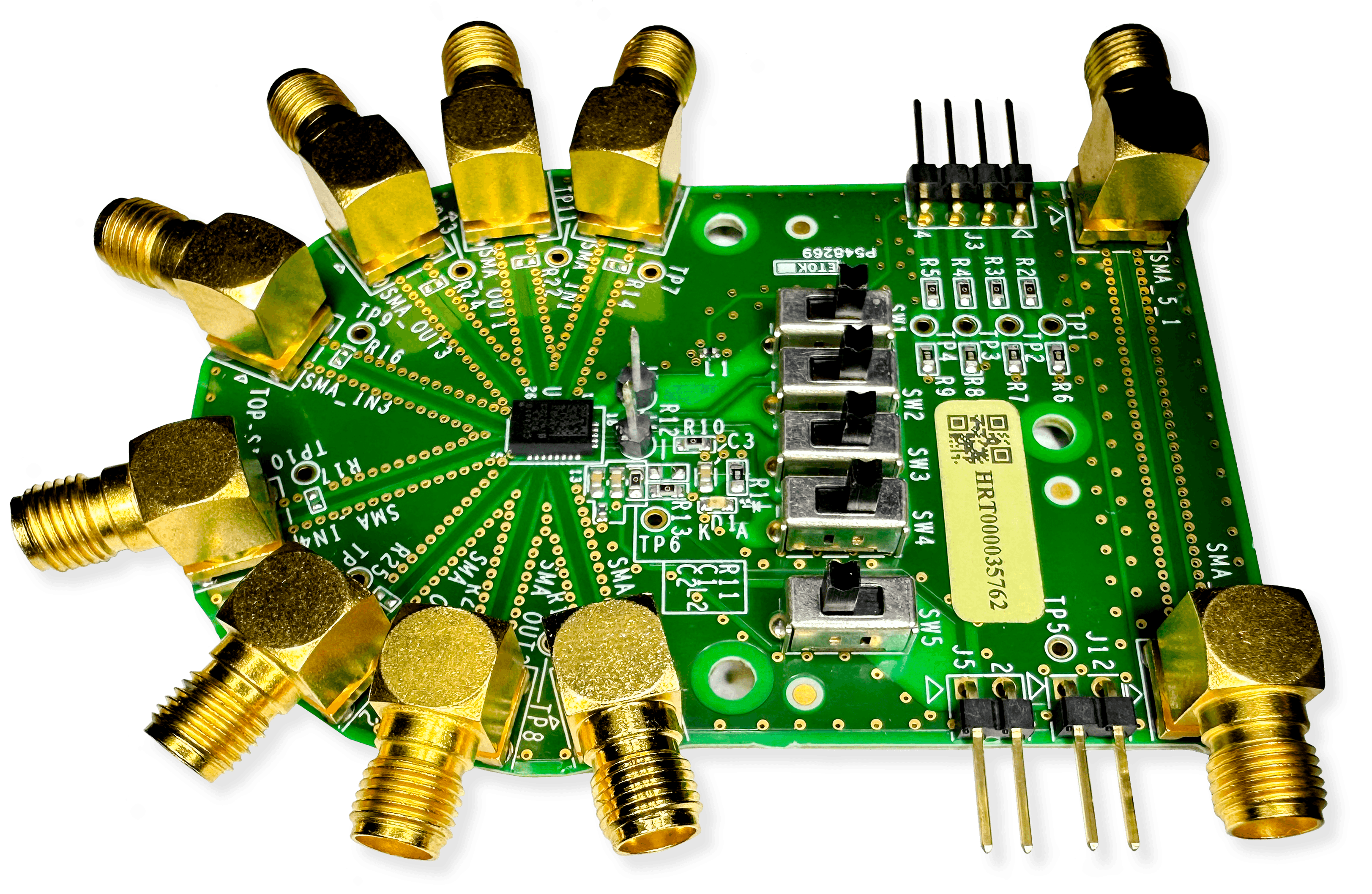

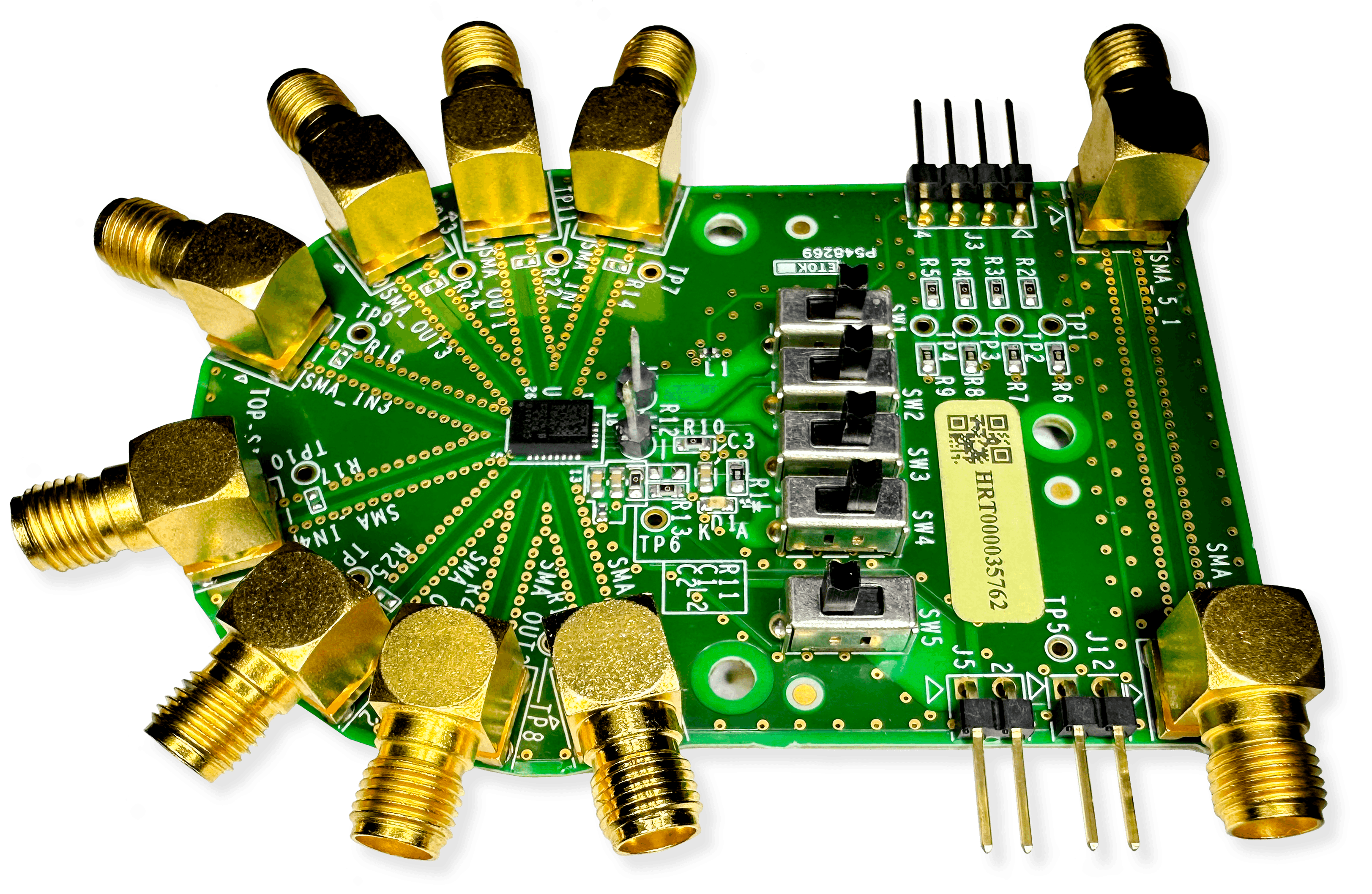

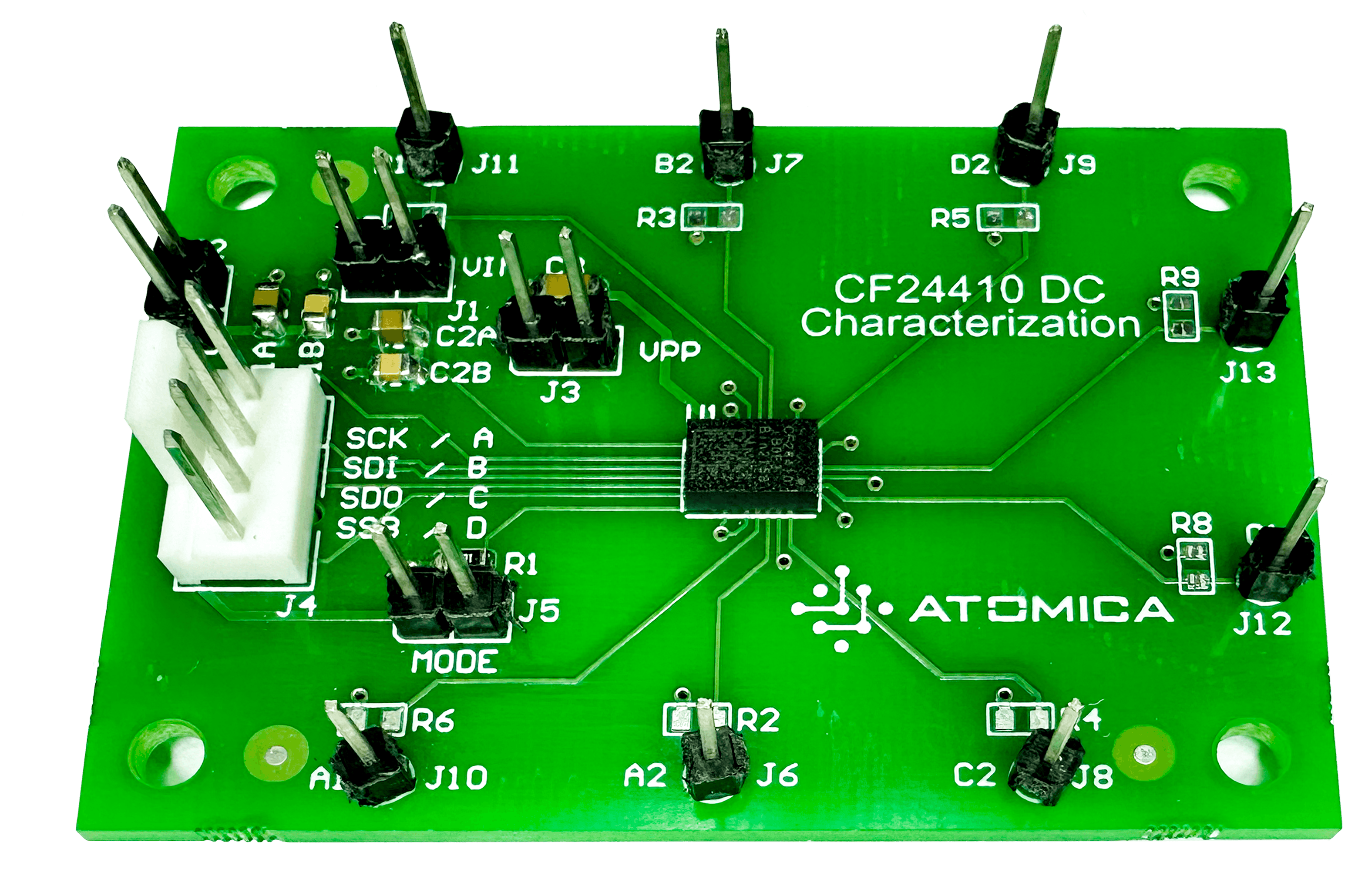

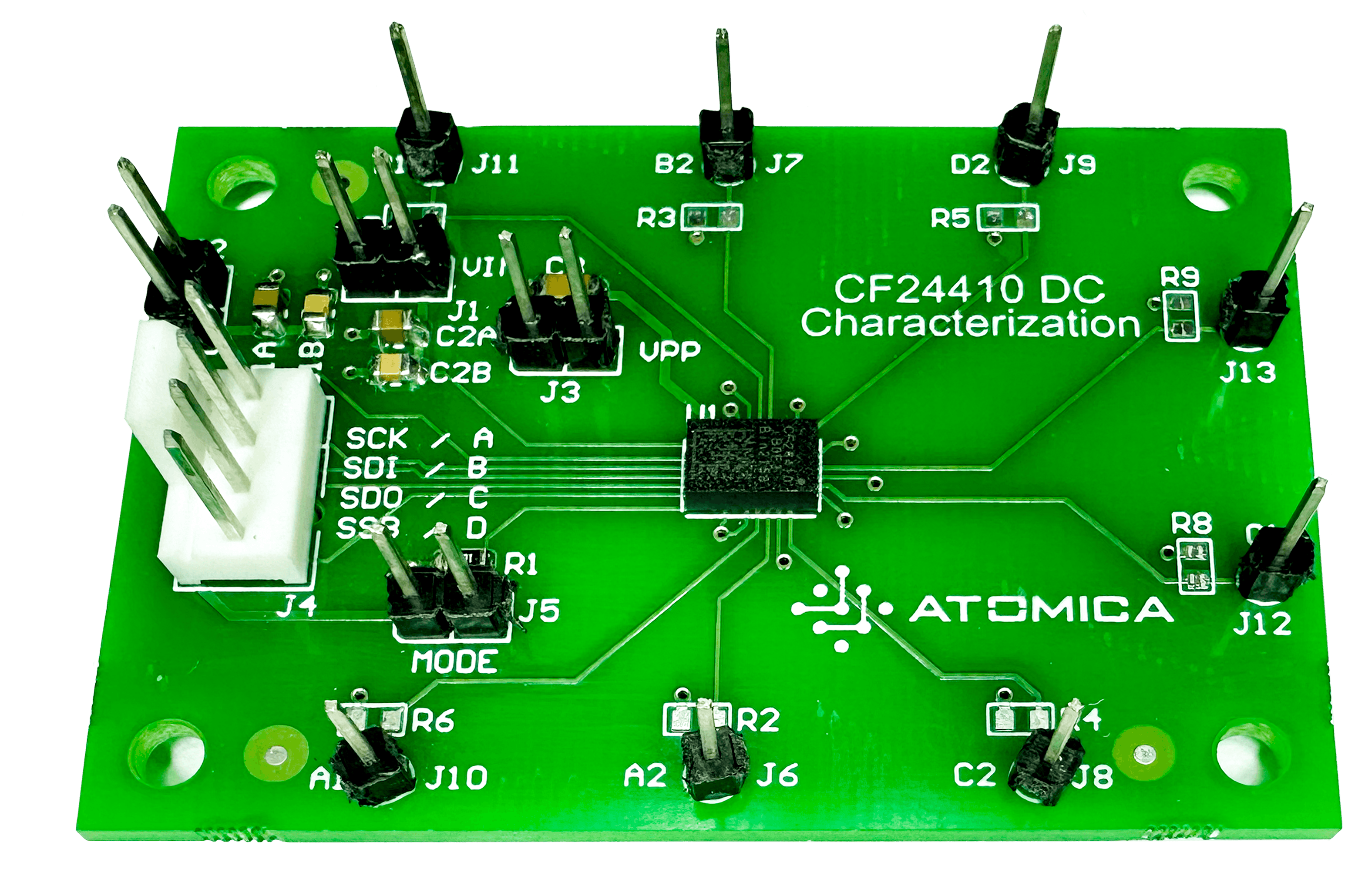

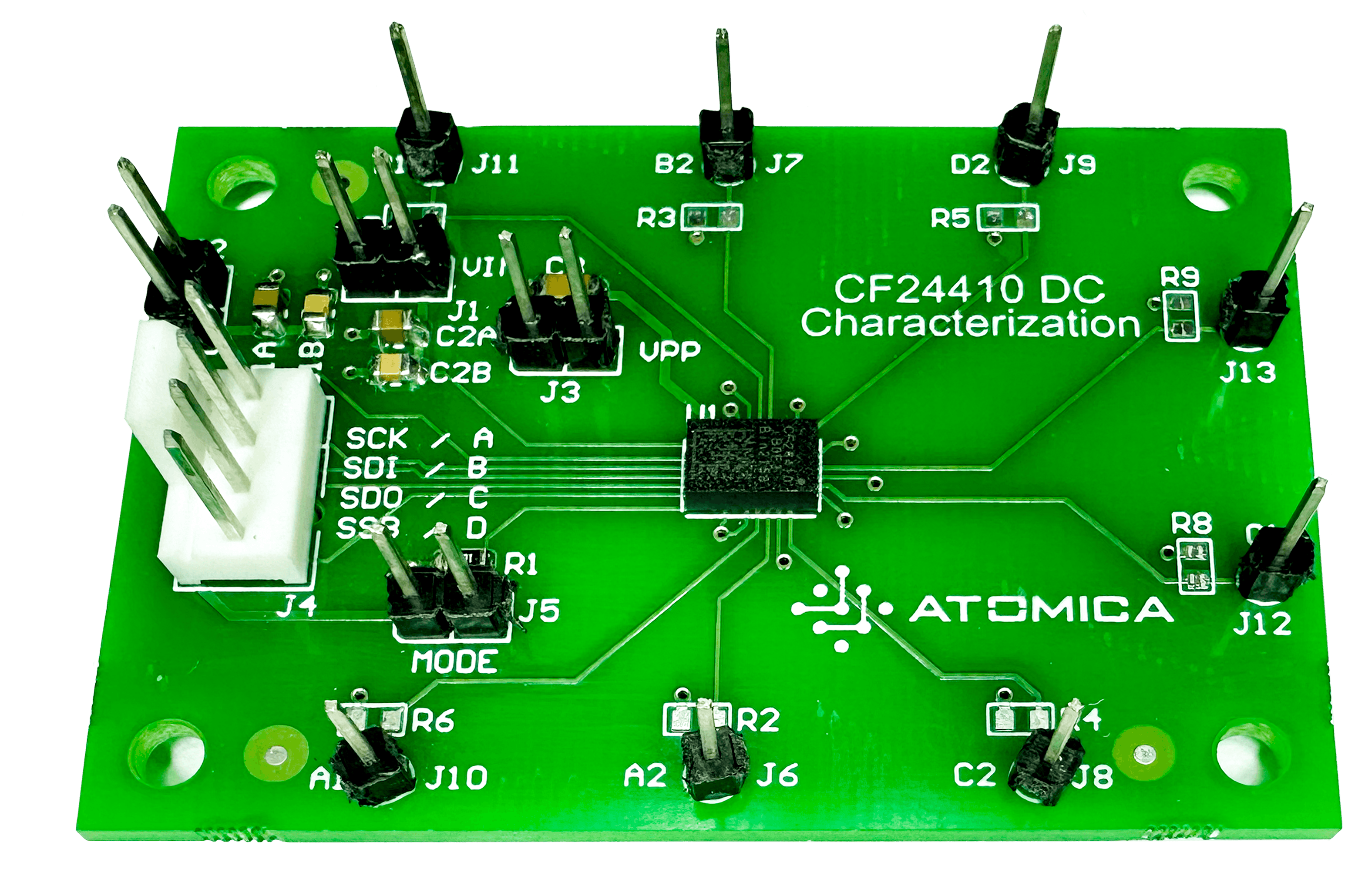

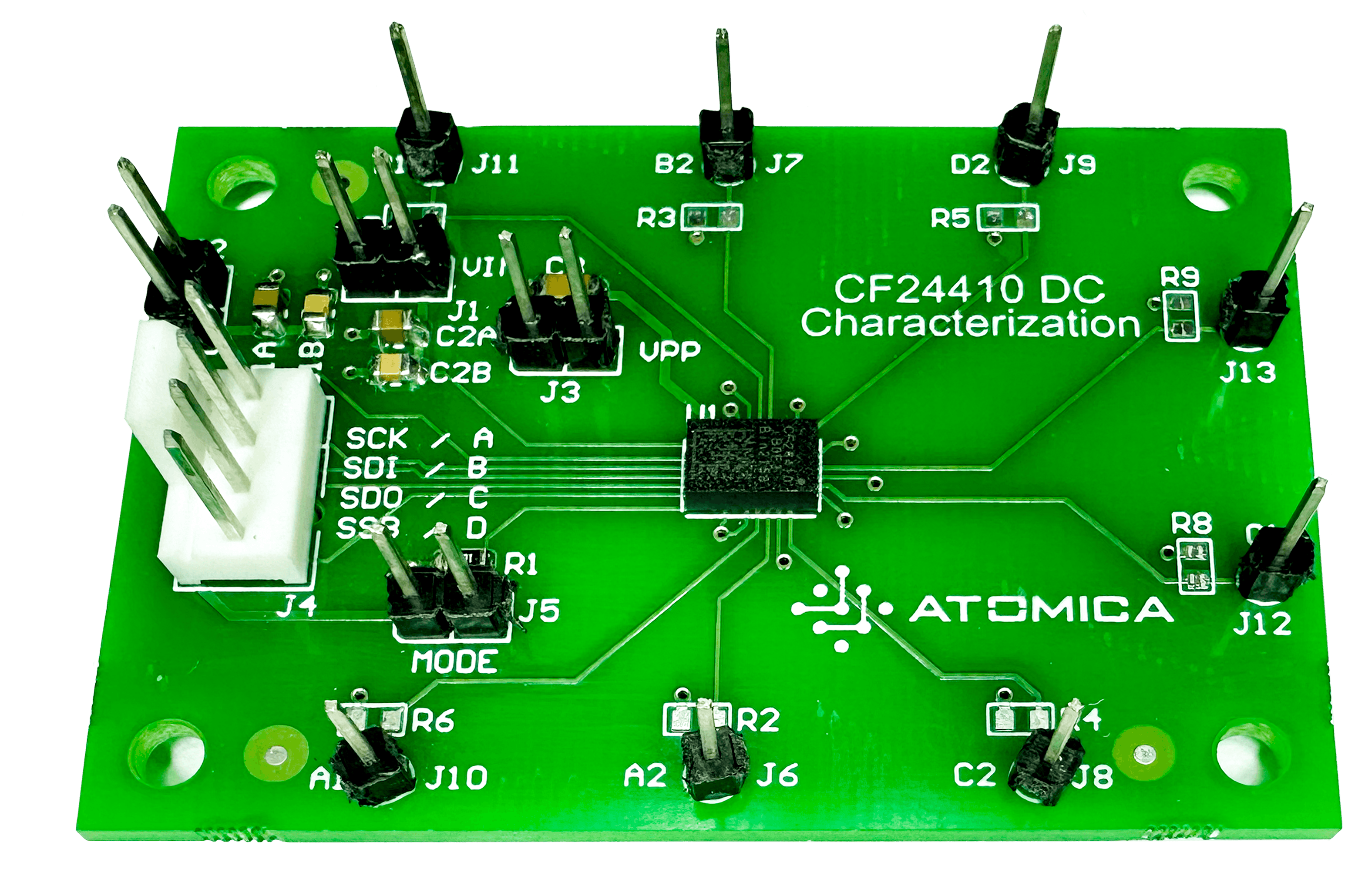

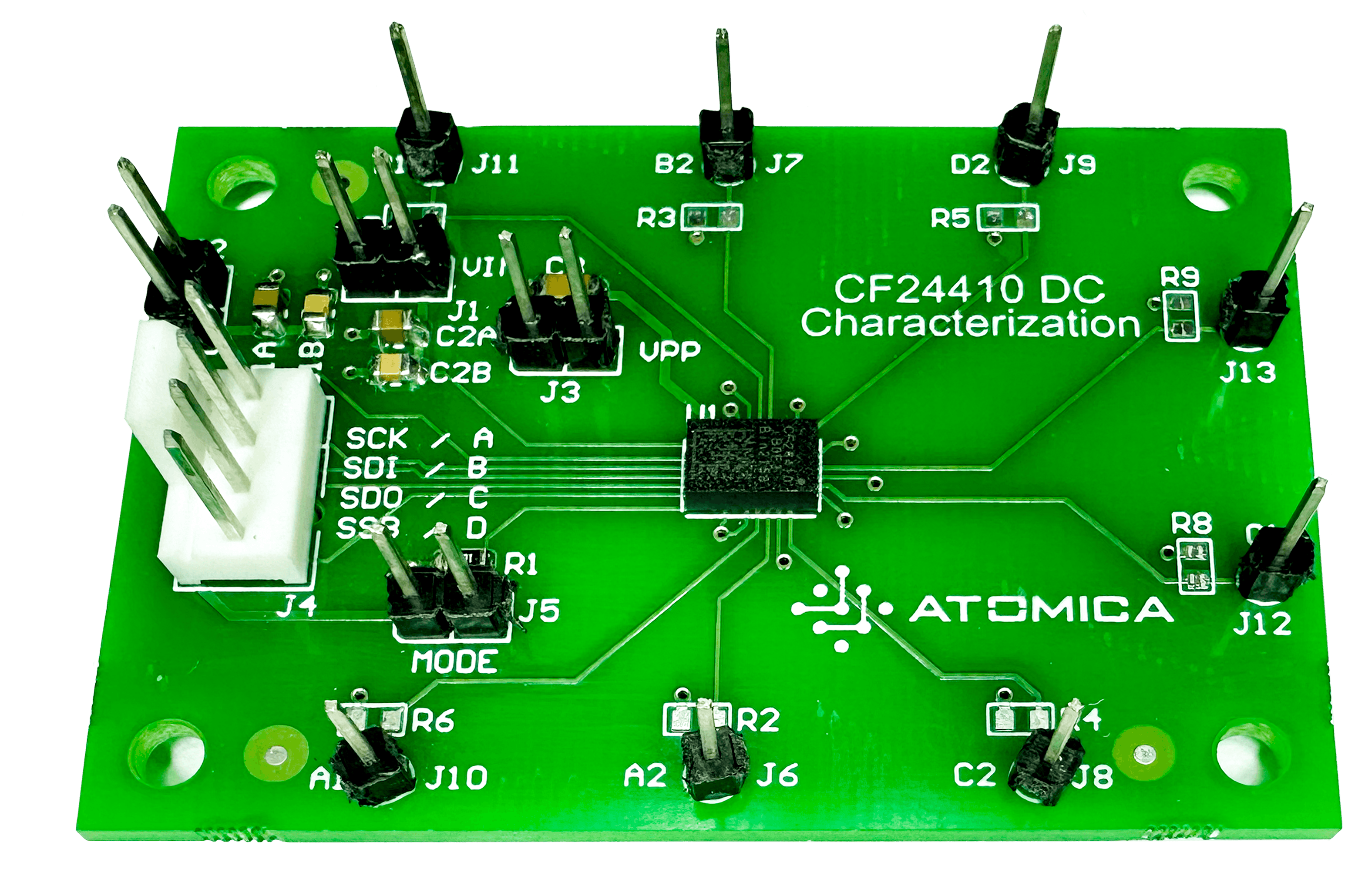

Evaluation board

Evaluation board

Evaluation board

We can provide you with test boards for DC and RF.

Fill the form and see if you qualify.

We can provide you with test boards for DC and RF. Fill the form and see if you qualify.

We can provide you with test boards for DC and RF. Fill the form and see if you qualify.

We can provide you with test boards for DC and RF. Fill the form and see if you qualify.

We can provide you with test boards for DC and RF. Fill the form and see if you qualify.

Want to learn more about our MEMS Switch?

Read more about our revolutionary MEMS switch.

Read more about our revolutionary MEMS switch.

Read more about our revolutionary MEMS switch.

Read more about our revolutionary MEMS switch.

Read more about our revolutionary MEMS switch.

Download the datasheet for technical specs

Download the datasheet for technical specs

Download the datasheet for technical specs

Download the datasheet for technical specs

Download the datasheet for technical specs

Talk to our technical team

to learn more

Talk to our technical team

to learn more

Talk to our technical team

to learn more

Talk to our technical team

to learn more

Talk to our technical team

to learn more

Cenfire Switching Platform Applications

Cenfire Switching Platform Applications

Cenfire Switching Platform Applications

Automated

Test Equipment

Application Highlight:

General Purpose Relay Card

Today test engineers spend critical development time programming FPGAs and calibrating signal integrity for a variety of relays and cables specialized for high-density test needs. A MEMS relay card is the pinnacle of flexibility, with ultra-high channel density that can handle AC, DC, high max current, high voltage isolation at a wide bandwidth. All of this with an endurance that will outlast the probe tips at 1B switching cycles.

1B

switching cycles

3X

reduction in downtime frequency for your production test

Electric Vehicles

Application Highlight:

Auxiliary Power Management Systems

Ancillary power management systems contribute meaningfully to the system-level efficiency of an electric vehicle. Power losses from electromechanical relays are a significant driver of this efficiency. Replacing these EMRs with Cenfire MEMS relays would result in a 99.9% reduction in power loss associated with contact electromagnet power dissipation.

15

more miles of range

99.9%

reduction in power loss

Medical Imaging

Application Highlight:

Point-of-Care Medical Imaging

Laboratory medical imaging systems use banks of high-voltage EMRs to switch transducers. Without the ability to switch many transducers, portable ultrasound systems have been forced to innovate on other aspects, such as the image reconstruction algorithm. With a 560x reduction in component volume, a MEMS switch bank reduces the constraint on transducer quantity, generating a massive leap in image resolution and SNR for PoC ultrasound technology.

-560x

in component volume

Benchtop quality medical imaging in a portable package

Consumer IoT

Application Highlight:

Smart Plug

Remote-controlled power switches are expected to proliferate with new IoT and AI applications. These smart plug designs are constrained by bulky, power-hungry, unreliable EMRs. Replacing with MEMS would allow for a slimmer design that actuates silently (no ugly clicking!). Compared to these EMRs, Cenfire's MEMS Relays save 2.24kWh per year in maintenance and actuation power draw.

2.24kWh

save per year in maintenance and actuation power draw

Automated Test Equipment

Application Highlight:

General Purpose Relay Card

Today test engineers spend critical development time programming FPGAs and calibrating signal integrity for a variety of relays and cables specialized for high-density test needs. A MEMS relay card is the pinnacle of flexibility, with ultra-high channel density that can handle AC, DC, high max current, high voltage isolation at a wide bandwidth. All of this with an endurance that will outlast the probe tips at 1B switching cycles.

1B

switching cycles

3X

reduction in downtime frequency for your production test

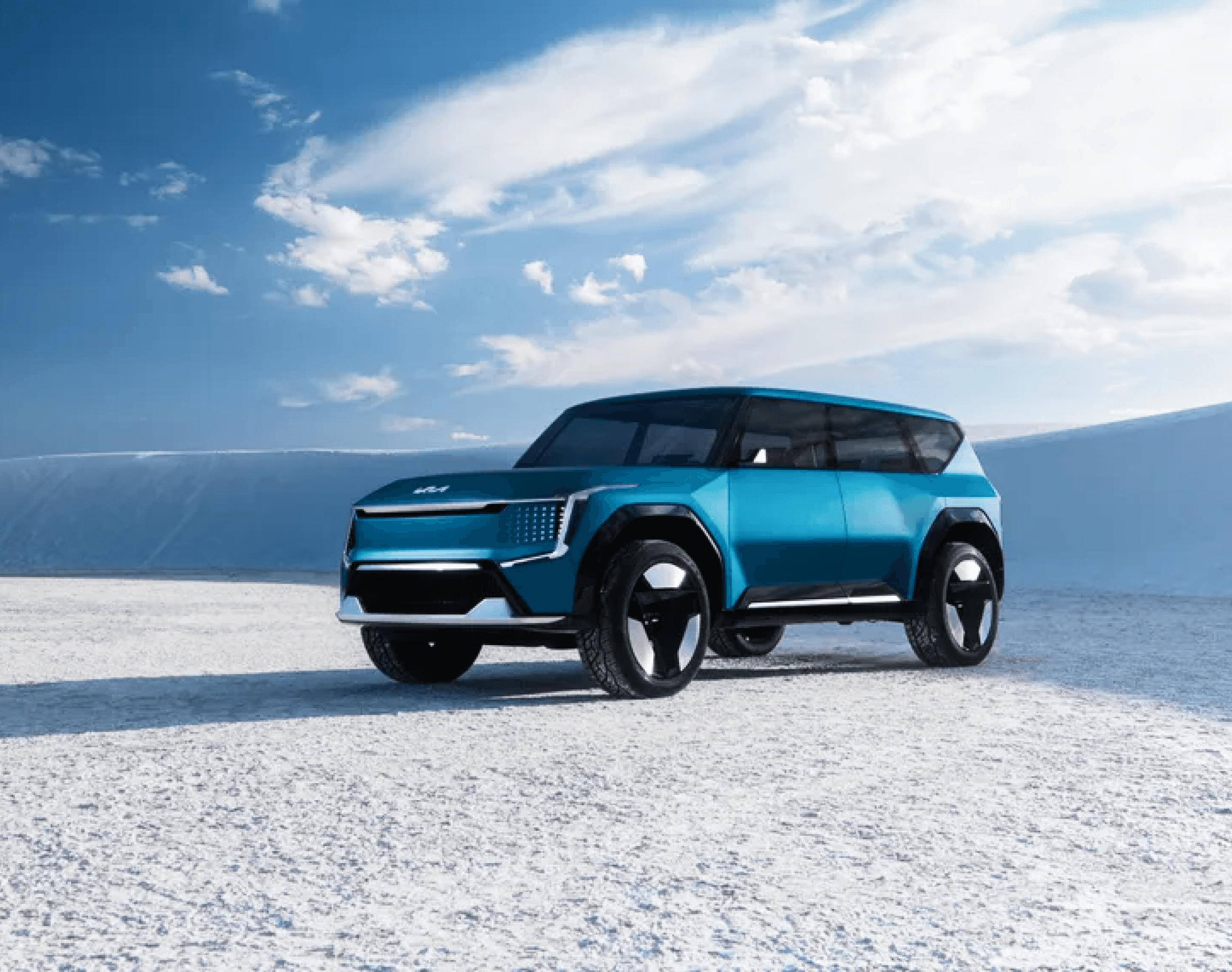

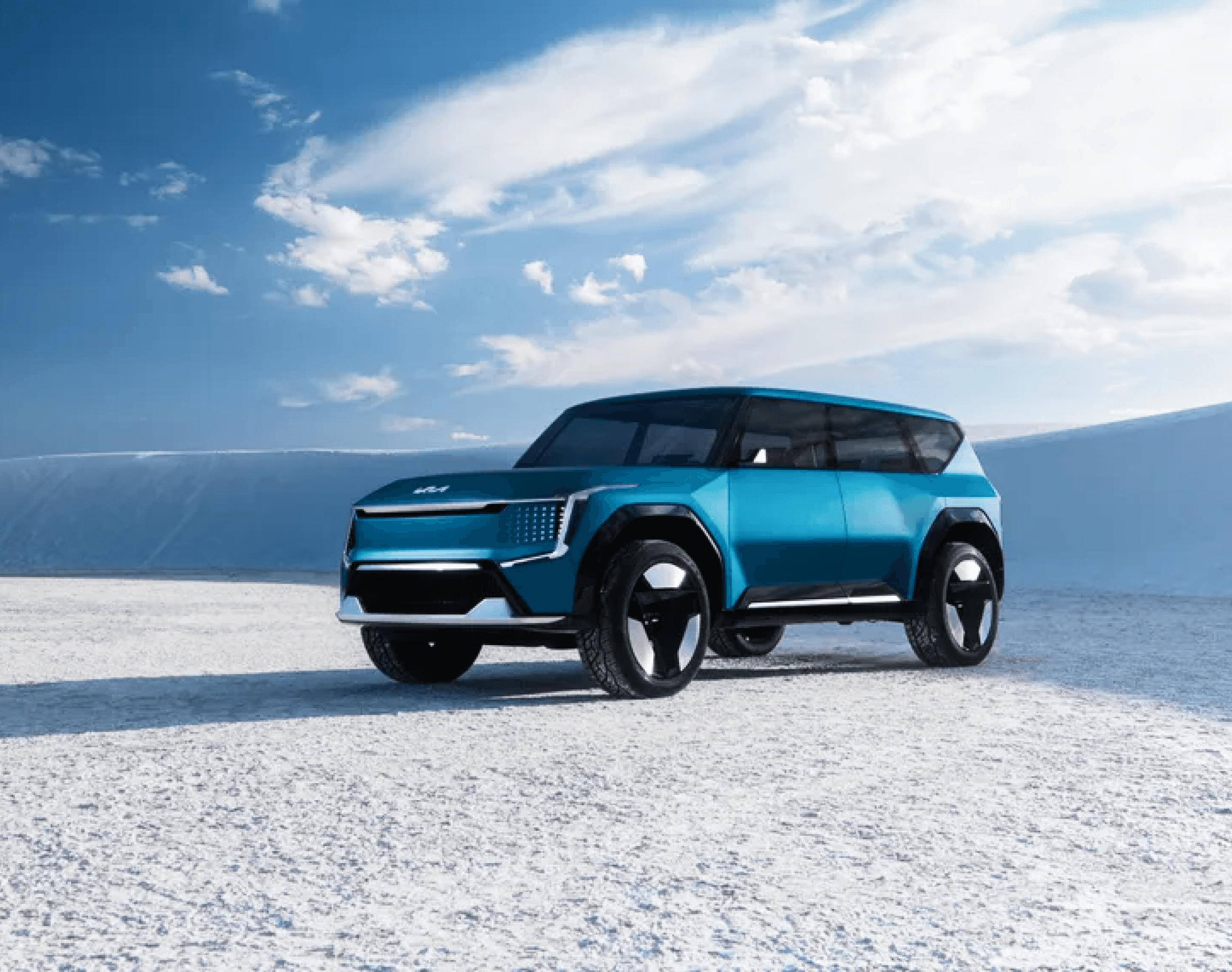

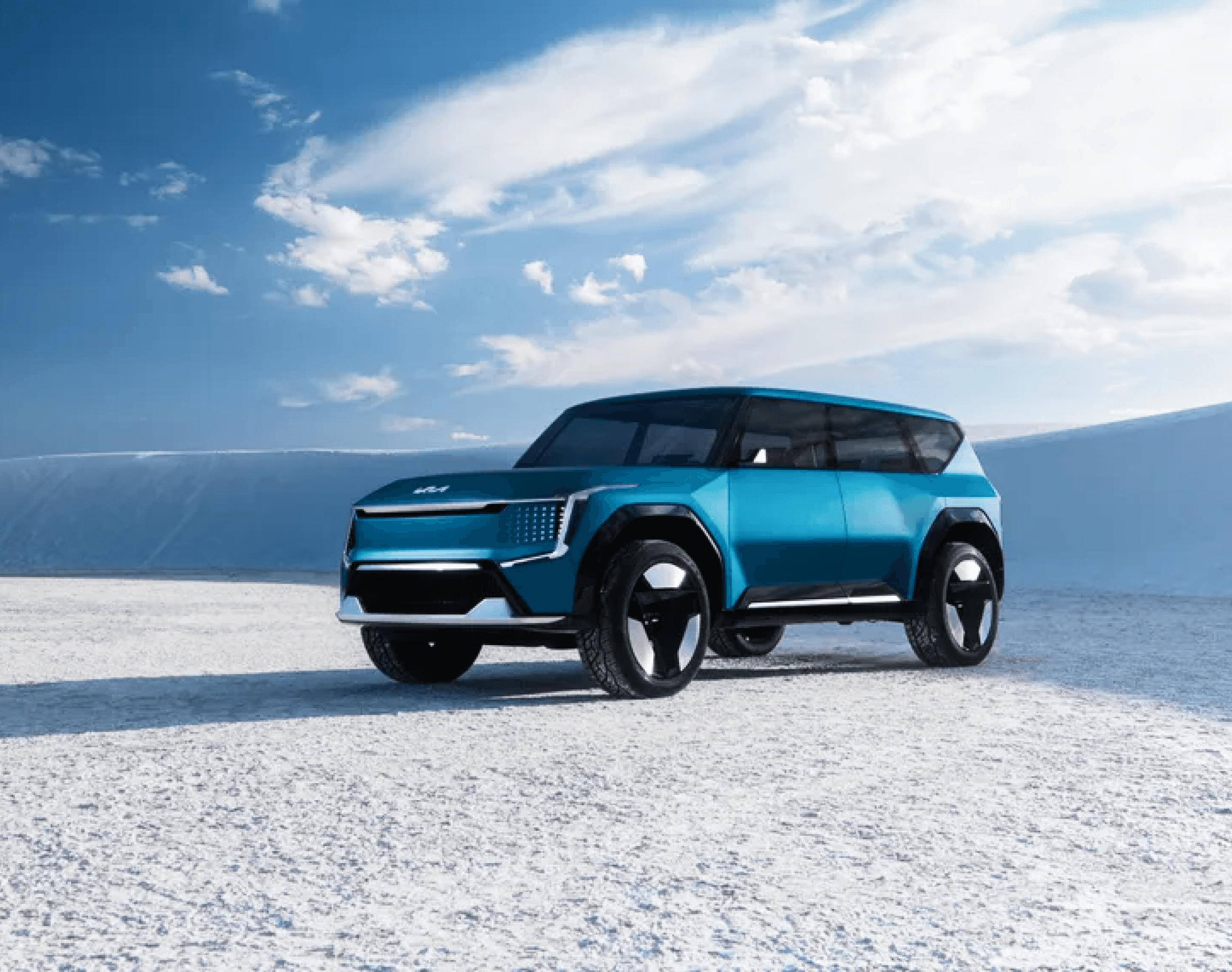

Electric Vehicles

Application Highlight:

Auxiliary Power Management Systems

Ancillary power management systems contribute meaningfully to the system-level efficiency of an electric vehicle. Power losses from electromechanical relays are a significant driver of this efficiency. Replacing these EMRs with Cenfire MEMS relays would result in a 99.9% reduction in power loss associated with contact electromagnet power dissipation.

15

more miles of range

99.9%

reduction in power loss

Medical Imaging

Application Highlight:

Point-of-Care Medical Imaging

Laboratory medical imaging systems use banks of high-voltage EMRs to switch transducers. Without the ability to switch many transducers, portable ultrasound systems have been forced to innovate on other aspects, such as the image reconstruction algorithm. With a 560x reduction in component volume, a MEMS switch bank reduces the constraint on transducer quantity, generating a massive leap in image resolution and SNR for PoC ultrasound technology.

-560x

in component volume

Benchtop quality medical imaging in a portable package

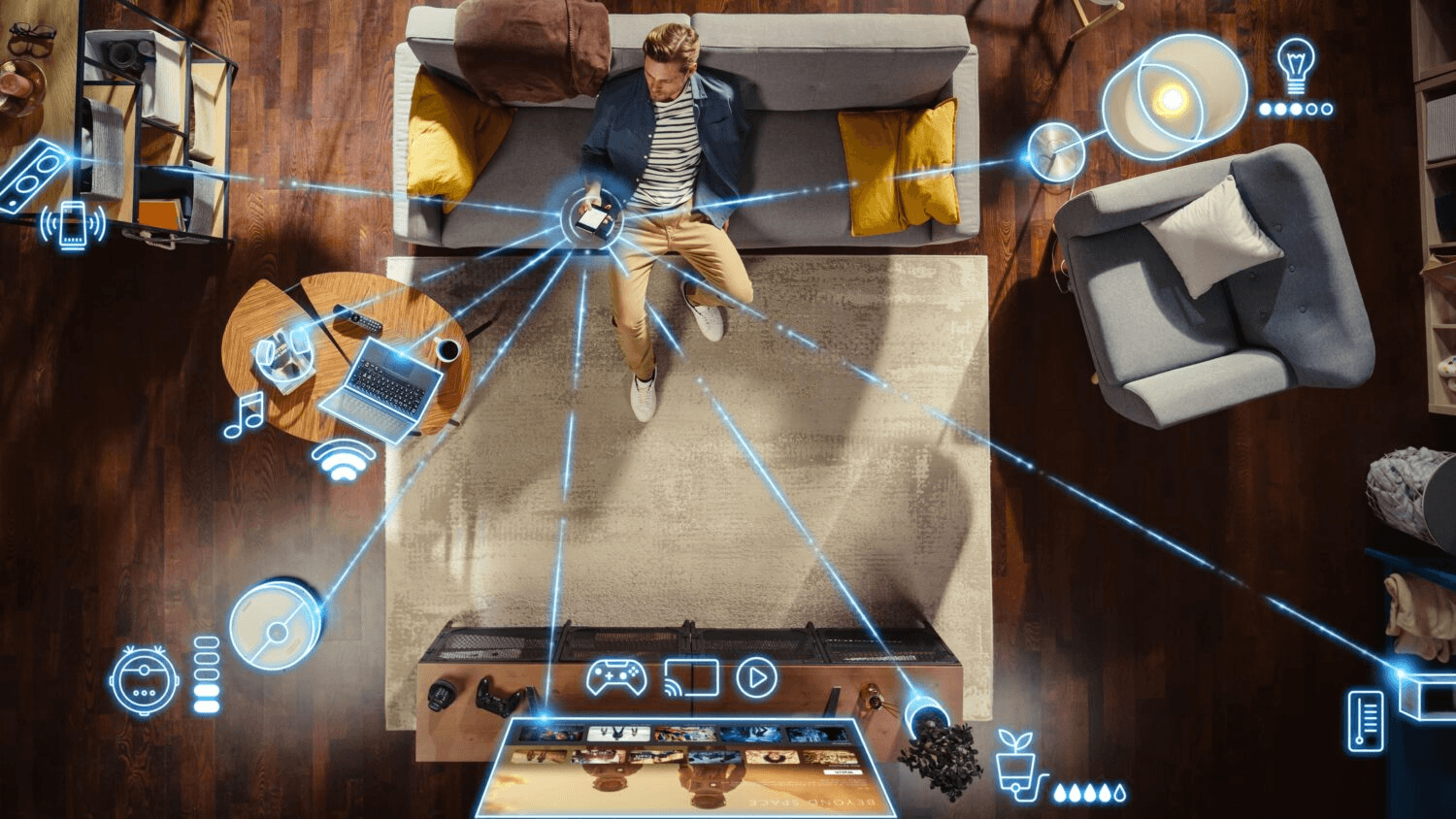

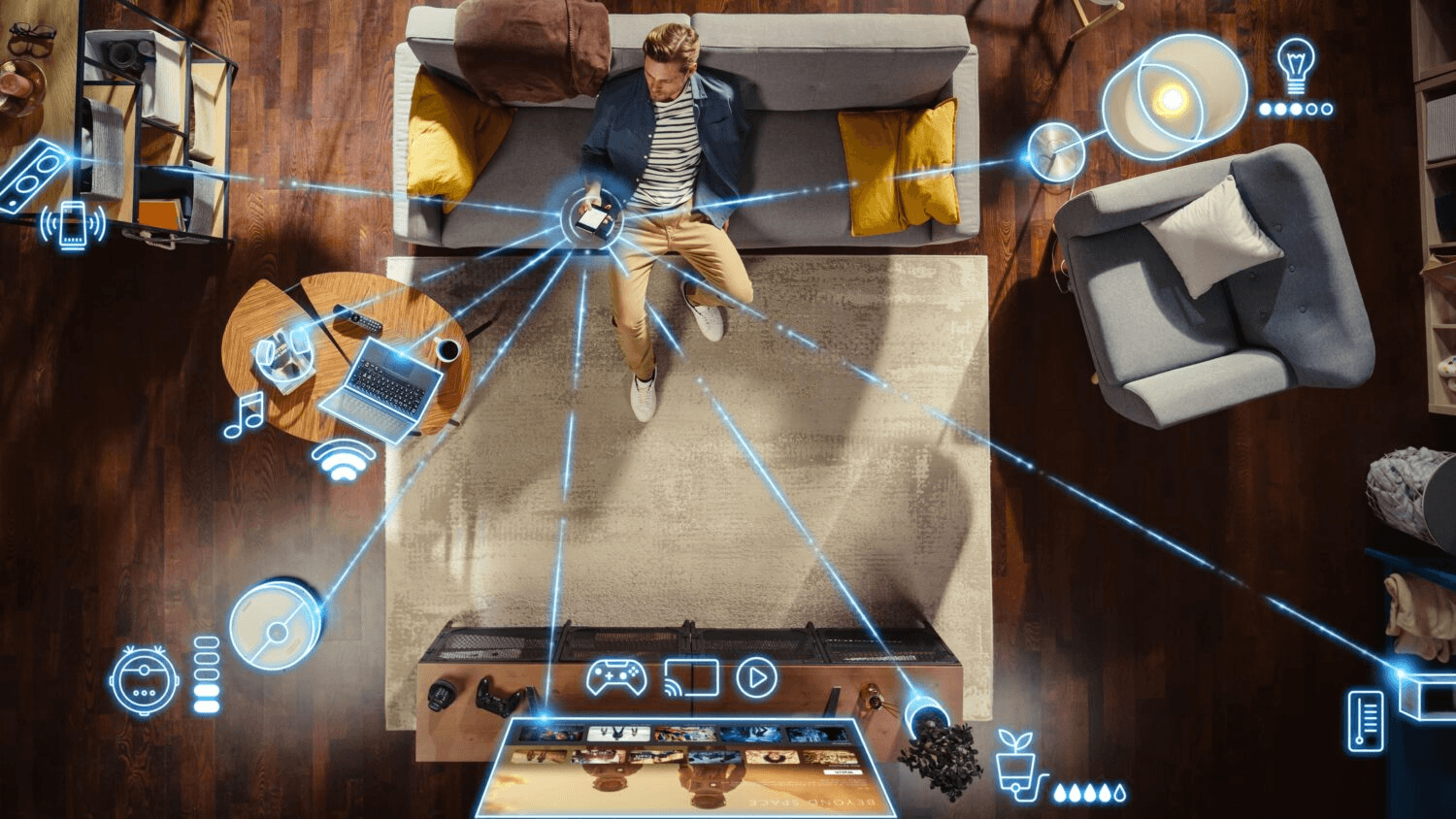

Consumer IoT

Application Highlight:

Smart Plug

Remote-controlled power switches are expected to proliferate with new IoT and AI applications. These smart plug designs are constrained by bulky, power-hungry, unreliable EMRs. Replacing with MEMS would allow for a slimmer design that actuates silently (no ugly clicking!). Compared to these EMRs, Cenfire's MEMS Relays save 2.24kWh per year in maintenance and actuation power draw.

2.24kWh

save per year in maintenance and actuation power draw

Automated Test Equipment

Application Highlight:

General Purpose Relay Card

Today test engineers spend critical development time programming FPGAs and calibrating signal integrity for a variety of relays and cables specialized for high-density test needs. A MEMS relay card is the pinnacle of flexibility, with ultra-high channel density that can handle AC, DC, high max current, high voltage isolation at a wide bandwidth. All of this with an endurance that will outlast the probe tips at 1B switching cycles.

1B

switching cycles

3X

reduction in downtime frequency for your production test

Electric Vehicles

Application Highlight:

Auxiliary Power Management Systems

Ancillary power management systems contribute meaningfully to the system-level efficiency of an electric vehicle. Power losses from electromechanical relays are a significant driver of this efficiency. Replacing these EMRs with Cenfire MEMS relays would result in a 99.9% reduction in power loss associated with contact electromagnet power dissipation.

15

more miles of range

99.9%

reduction in power loss

Medical Imaging

Application Highlight:

Point-of-Care Medical Imaging

Laboratory medical imaging systems use banks of high-voltage EMRs to switch transducers. Without the ability to switch many transducers, portable ultrasound systems have been forced to innovate on other aspects, such as the image reconstruction algorithm. With a 560x reduction in component volume, a MEMS switch bank reduces the constraint on transducer quantity, generating a massive leap in image resolution and SNR for PoC ultrasound technology.

-560x

in component volume

Benchtop quality medical imaging in a portable package

Consumer IoT

Application Highlight:

Smart Plug

Remote-controlled power switches are expected to proliferate with new IoT and AI applications. These smart plug designs are constrained by bulky, power-hungry, unreliable EMRs. Replacing with MEMS would allow for a slimmer design that actuates silently (no ugly clicking!). Compared to these EMRs, Cenfire's MEMS Relays save 2.24kWh per year in maintenance and actuation power draw.

2.24kWh

save per year in maintenance and actuation power draw

Automated Test Equipment

Application Highlight:

General Purpose Relay Card

Today test engineers spend critical development time programming FPGAs and calibrating signal integrity for a variety of relays and cables specialized for high-density test needs. A MEMS relay card is the pinnacle of flexibility, with ultra-high channel density that can handle AC, DC, high max current, high voltage isolation at a wide bandwidth. All of this with an endurance that will outlast the probe tips at 1B switching cycles.

1B

switching cycles

3X

reduction in downtime frequency for your production test

Electric Vehicles

Application Highlight:

Auxiliary Power Management Systems

Ancillary power management systems contribute meaningfully to the system-level efficiency of an electric vehicle. Power losses from electromechanical relays are a significant driver of this efficiency. Replacing these EMRs with Cenfire MEMS relays would result in a 99.9% reduction in power loss associated with contact electromagnet power dissipation.

15

more miles of range

99.9%

reduction in power loss

Medical Imaging

Application Highlight:

Point-of-Care Medical Imaging

Laboratory medical imaging systems use banks of high-voltage EMRs to switch transducers. Without the ability to switch many transducers, portable ultrasound systems have been forced to innovate on other aspects, such as the image reconstruction algorithm. With a 560x reduction in component volume, a MEMS switch bank reduces the constraint on transducer quantity, generating a massive leap in image resolution and SNR for PoC ultrasound technology.

-560x

in component volume

Benchtop quality medical imaging in a portable package

Consumer IoT

Application Highlight:

Smart Plug

Remote-controlled power switches are expected to proliferate with new IoT and AI applications. These smart plug designs are constrained by bulky, power-hungry, unreliable EMRs. Replacing with MEMS would allow for a slimmer design that actuates silently (no ugly clicking!). Compared to these EMRs, Cenfire's MEMS Relays save 2.24kWh per year in maintenance and actuation power draw.

2.24kWh

save per year in maintenance and actuation power draw

Automated

Test Equipment

Application Highlight:

General Purpose Relay Card

Today test engineers spend critical development time programming FPGAs and calibrating signal integrity for a variety of relays and cables specialized for high-density test needs. A MEMS relay card is the pinnacle of flexibility, with ultra-high channel density that can handle AC, DC, high max current, high voltage isolation at a wide bandwidth. All of this with an endurance that will outlast the probe tips at 1B switching cycles.

1B

switching cycles

3X

reduction in downtime frequency for your production test

Electric Vehicles

Application Highlight:

Auxiliary Power Management Systems

Ancillary power management systems contribute meaningfully to the system-level efficiency of an electric vehicle. Power losses from electromechanical relays are a significant driver of this efficiency. Replacing these EMRs with Cenfire MEMS relays would result in a 99.9% reduction in power loss associated with contact electromagnet power dissipation.

15

more miles of range

99.9%

reduction in power loss

Medical Imaging

Application Highlight:

Point-of-Care Medical Imaging

Laboratory medical imaging systems use banks of high-voltage EMRs to switch transducers. Without the ability to switch many transducers, portable ultrasound systems have been forced to innovate on other aspects, such as the image reconstruction algorithm. With a 560x reduction in component volume, a MEMS switch bank reduces the constraint on transducer quantity, generating a massive leap in image resolution and SNR for PoC ultrasound technology.

-560x

in component volume

Benchtop quality medical imaging in a portable package

Consumer IoT

Application Highlight:

Smart Plug

Remote-controlled power switches are expected to proliferate with new IoT and AI applications. These smart plug designs are constrained by bulky, power-hungry, unreliable EMRs. Replacing with MEMS would allow for a slimmer design that actuates silently (no ugly clicking!). Compared to these EMRs, Cenfire's MEMS Relays save 2.24kWh per year in maintenance and actuation power draw.

2.24kWh

save per year in maintenance and actuation power draw

Automated

Test Equipment

Application Highlight:

General Purpose Relay Card

Today test engineers spend critical development time programming FPGAs and calibrating signal integrity for a variety of relays and cables specialized for high-density test needs. A MEMS relay card is the pinnacle of flexibility, with ultra-high channel density that can handle AC, DC, high max current, high voltage isolation at a wide bandwidth. All of this with an endurance that will outlast the probe tips at 1B switching cycles.

1B

switching cycles

3X

reduction in downtime frequency for your production test

Electric Vehicles

Application Highlight:

Auxiliary Power Management Systems

Ancillary power management systems contribute meaningfully to the system-level efficiency of an electric vehicle. Power losses from electromechanical relays are a significant driver of this efficiency. Replacing these EMRs with Cenfire MEMS relays would result in a 99.9% reduction in power loss associated with contact electromagnet power dissipation.

15

more miles of range

99.9%

reduction in power loss

Medical Imaging

Application Highlight:

Point-of-Care Medical Imaging

Laboratory medical imaging systems use banks of high-voltage EMRs to switch transducers. Without the ability to switch many transducers, portable ultrasound systems have been forced to innovate on other aspects, such as the image reconstruction algorithm. With a 560x reduction in component volume, a MEMS switch bank reduces the constraint on transducer quantity, generating a massive leap in image resolution and SNR for PoC ultrasound technology.

-560x

in component volume

Benchtop quality medical imaging in a portable package

Consumer IoT

Application Highlight:

Smart Plug

Remote-controlled power switches are expected to proliferate with new IoT and AI applications. These smart plug designs are constrained by bulky, power-hungry, unreliable EMRs. Replacing with MEMS would allow for a slimmer design that actuates silently (no ugly clicking!). Compared to these EMRs, Cenfire's MEMS Relays save 2.24kWh per year in maintenance and actuation power draw.

2.24kWh

save per year in maintenance and actuation power draw